The Critical Nature of Surface Preparation

When we talk to new customers in the early stages of our sales process, concrete preparation is always a key topic that is discussed. Due to how important it is to the overall success of the flooring installation. It is easy to show a new customer pretty samples, different color selections, textures, and creative finishes, but what is not talked about is how the concrete substrate is going to be prepared and what methods we will use to complete the preparation.

Concrete preparation is the number one step that has to be completed correctly when installing any type of resinous flooring system. If the concrete substrate or existing coating is not prepared correctly with the proper machine, the new floor system will fail! It is just a matter of time when that will happen.

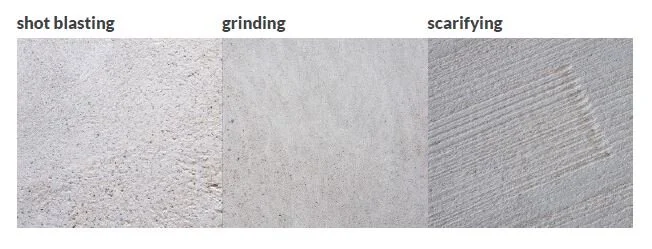

Mechanical concrete preparation methods used at T.W. Hicks, Inc. are Shot Blasting, Grinding, and Scarifying. All three methods provide different profiles to achieve the best adhesion for the floor system being installed. Sometimes it might take all three methods to get the job done correctly. All of these methods of mechanical preparation are paired with dust collection units that are specifically designed to reduce dust and debris, providing a cleaner and safer work environment.

SHOT BLASTING

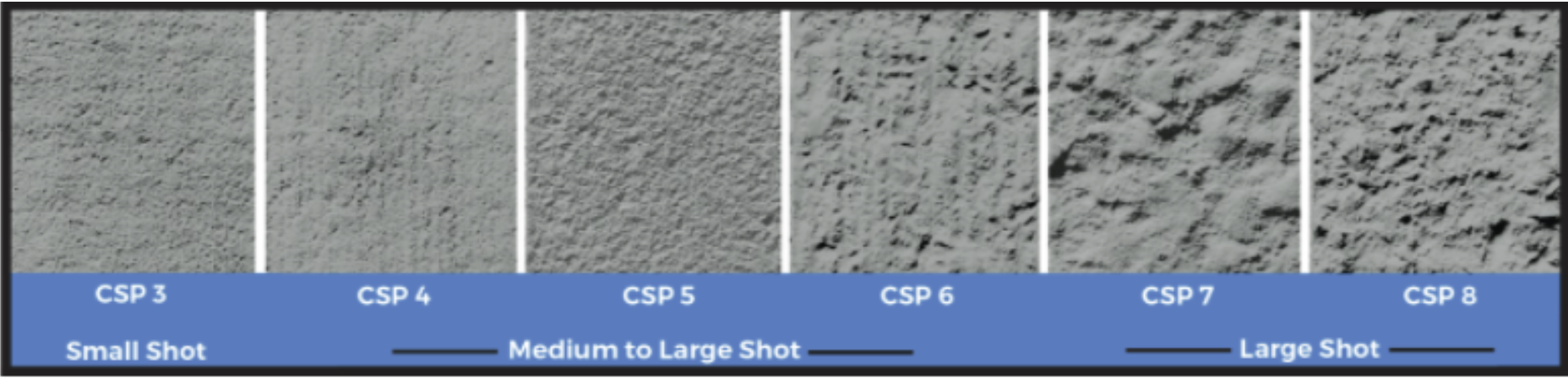

Shot Blasting is a cost effective and environmentally friendly method for preparing concrete substrates. Shot Blasting machines come in a variety of different sizes to match the job at hand. T.W. Hicks, Inc. uses small 8” machines to do edge prep against vertical walls and small spaces where larger equipment cannot reach. For larger scale projects where high production rates are required we will use machines up to 20”. Shot Blasting provides the perfect profile for adhesion to concrete substrates and is a recognized method of preparation by most product manufacturers. Shot Blasting equipment can provide CSP profiles from 3 to 8 depending on the size shot used and the speed setting on the machine.

Blastrac Shot Blasting Machine: https://www.blastrac.com/machines/shot-blasting/

GRINDING

Grinding has become a very popular concrete preparation method since the concrete polishing movement. Diamond grinders used in the polishing process have made a huge impact on how we use grinders as a mechanical preparation tool. Advancements in diamonds that are used make grinding a great way to achieve a CSP 1-3 profile for thinner resinous flooring systems without getting blast lines in the concrete substrate that can telegraph through on thinner resinous flooring systems. Grinding is also a great way to remove failing thin film resinous coating systems, mastics under tile, and thin set grout without damaging the concrete substrate below the coating. Grinding can also be used to profile existing resinous floor systems for recoats. The vacuum systems used on grinding equipment allows us to be able to control the dust and debris, unlike traditional orbital sanders loaded with sanding screens when doing a sand and recoat.

Blastrac Grinding/ Polishing Machine: https://www.blastrac.com/grinding-polishing/

SCARIFYING

Scarifying is an aggressive preparation method that we use when we are removing an existing resinous flooring system that is typically ⅛” to ⅜” thick and has the same type of resinous flooring system being installed back in the same area. Scarifiers use steel or carbide tipped cutters that are loaded on shafts to create a cylindrical drum. The drum rotates the cutters, allowing them to cut the concrete or failed resinous flooring system. Scarifying can also be used to remove high spots in concrete slabs or level out joints that have curled. Scarifying is the most aggressive preparation method that we use. It is very important to understand that you have to match the system to the prep method when using this method of preparation. You would not want to scarify the concrete and install a 20 mil coating system. Your customer would not be happy with the end result!

USING ALL 3 METHODS

There are always those jobs that may require multiple prep methods. This can occur when we have to remove an existing resinous floor and replace it with a specific resinous floor system that the customer might want. We might utilize the scarifying method to remove and grind it to flatten the profile so that a ⅛” system can be installed instead of a thicker system.

If someone says that they are going to acid etch your concrete substrate and install your new resinous flooring system, call us for the best floor contractors immediately!